Greige Fabric Quality.

Best quality yarn is purchased and inspected before sending it to for knitting.

100% fabric is inspected by skilled inspectors for bands, variation, oil line, needle line, sinker lines and knit holes. Ultra violet light source is used to check for bands & variation in fabric.

Dyed Fabric Quality.

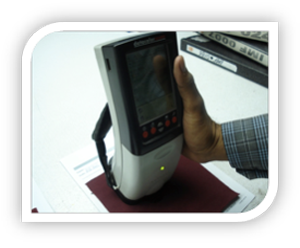

Data Colour Spectrophotometer is used to measure precise colour readings to ensure colour consistency. Standard CMC 1.0

Every inch of the fabric is inspected for any faults in dyeing. Crocking, shrinkage and color fastness.

Cut Panels Quality.

Each cut part is checked and audited.

Tech-packs are made according to approved pre-production sample and style details for bulk production according to customer requirements and are referred to at all inspection stages.

Final Audit.

Final audit of packed finished goods is done at AQL 2.5 to ensure quality goods are shipped.

Each carton is marked with audit report number and has unique barcode which ensures accuracy in shipping.

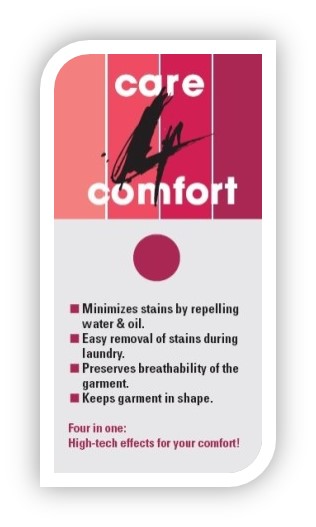

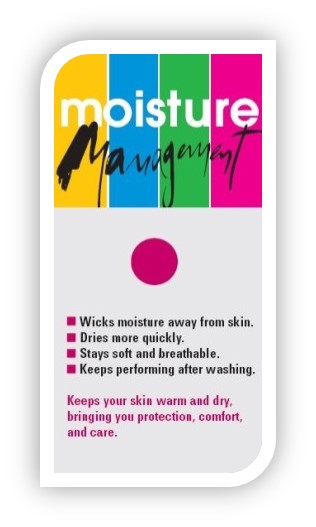

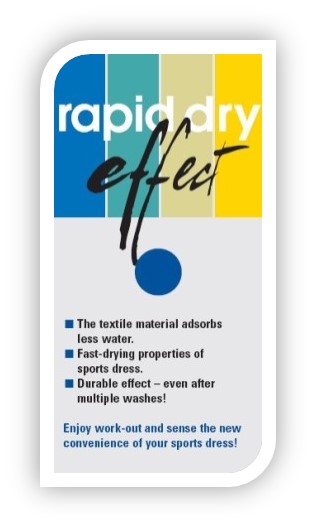

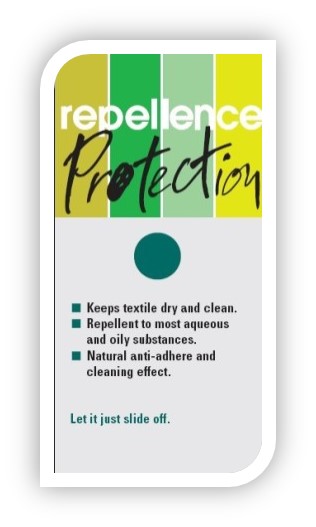

Special Fabrics / Finishes.

We believe in innovation, that is why are constantly developing new fabrics and finishes. We are aware of uniform apparel’s long lasting durability needs that’s why are making special fabrics to meet industry’s requirements.